A digital S&OP and S&OE can bring much better long-term visibility, enables end-to-end dynamic business planning, and substantially increase the operational efficiency and effectiveness.

In today’s world, it is not enough to save “the today, this week or next week”, as flour business is getting more complex every day. The ability to think long term is more critical than ever. Effective long-term planning creates enormous benefits to the companies’ topline and leads to significant operational efficiency and effectiveness, particularly when it is combined with data analytics and digital tools. That’s why, Digital S&OP (Sales and Operations Planning) is becoming vital for the organizations to stay ahead of competition and streamline their operations while being ready for future.

Flour milling business is more complex than ever

Flour business is not a stable business anymore. In the last 5 years, complexity has significantly increased, and the pandemic boosted complexity even more. Shift in demand is much faster and challenges in supply chain are way beyond the expectations.

On demand side, consumer preferences are shifting towards healthier options such as organic wheat, ancient grains, and pulses. Food applications once relying primarily on wheat flour are being re-invented with alternative grain types. Despite this long-term shift in preferences, inflation is now forcing consumers to trade down and increase their demand for lower priced options. In addition, Covid-19 triggered swift changes in where consumption is happening (at home vs out of home). Thus, flour demand of different milling customer segments shifted unexpectedly in the last two years.

On the other hand, number of supply issues have emerged. Price increases in grains, changes in wheat supply routes, labor availability, truck shortages are all factors increasing supply challenges.

We do not expect these changes and challenges to vanish in the short-term; consumer preferences will continue to evolve and supply chain challenges will not be resolved soon. Therefore, it will be important to develop the best-in-class planning capabilities for milling companies.

How structured, data-driven planning leads to operational efficiency

There is certainly a need to establish a structured approach for short-term and long-term planning and ensure milling companies are ready for opportunities and risks in the market. There is already a bullet-proof concept called S&OP (Sales and Operations Planning) and S&OE (Sales and Operations Execution) that are widely used in leading consumer goods and manufacturing companies. On the other hand, milling industry is still in process of adopting S&OP and S&OE processes and many milling companies that run S&OP do not effectively utilize the data and information; therefore, they are not able to focus their discussions to long-term challenges and trade-offs effectively.

Today, leading companies who already adopted S&OP and S&OE are putting their focus on digitalization of their S&OP and S&OE processes with data and analytics driven technologies. A digital S&OP and S&OE can bring much better long-term visibility, enables end-to-end dynamic business planning, and substantially increase the operational efficiency and effectiveness.

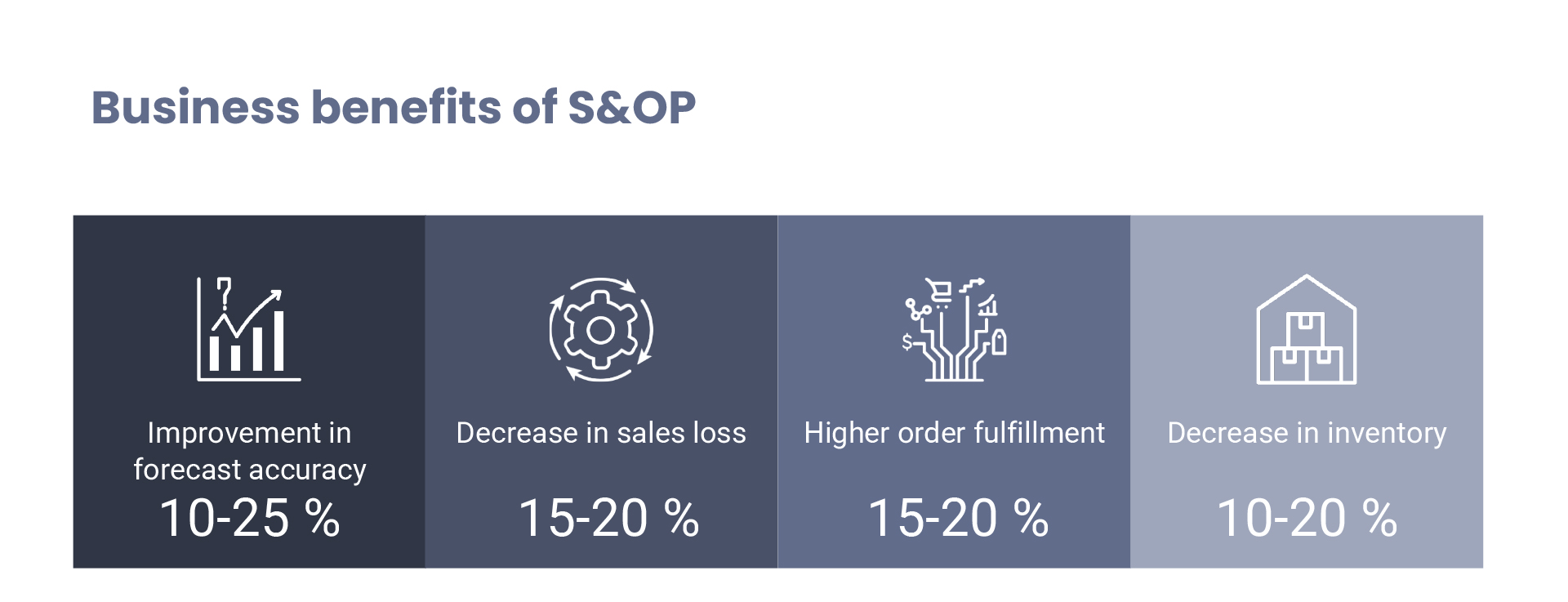

Successfully implemented Digital S&OP & S&OE reflects itself in business results as well.

Exhibit 1

S&OP (Sales & Operations Planning) is all about long-term planning

S&OP requires a step change in the way businesses think, plan, and make decisions. S&OP is a monthly process that gives a long-term view (from 3 to 18/24 months). S&OP takes place in 4 review sessions within the month: (1) demand, (2) supply, (3) reconciliation, and (4) executive review. In each of these review sessions, there are continuous fact-based discussions about the market, competition, and customers. Based on market expectations, supply plans are prepared considering different scenarios to optimize what, when and where to produce. Comparing demand and supply, management teams make decisions on which product categories and customer segments to prioritize, how to plan actions to address the gaps and mitigate the risks in the future.

S&OE (Sales & Operations Execution) prevents firefighting when there is a change in plans

S&OE is a weekly process on short term (0-8 weeks) where cross-functional teams talk about the changes and variances in their sales forecast, customer orders, sourcing, production, and transportation plans. S&OE aims to identify short term challenges and plan proactively for those so that companies can be proactive rather than being in firefighting mode.

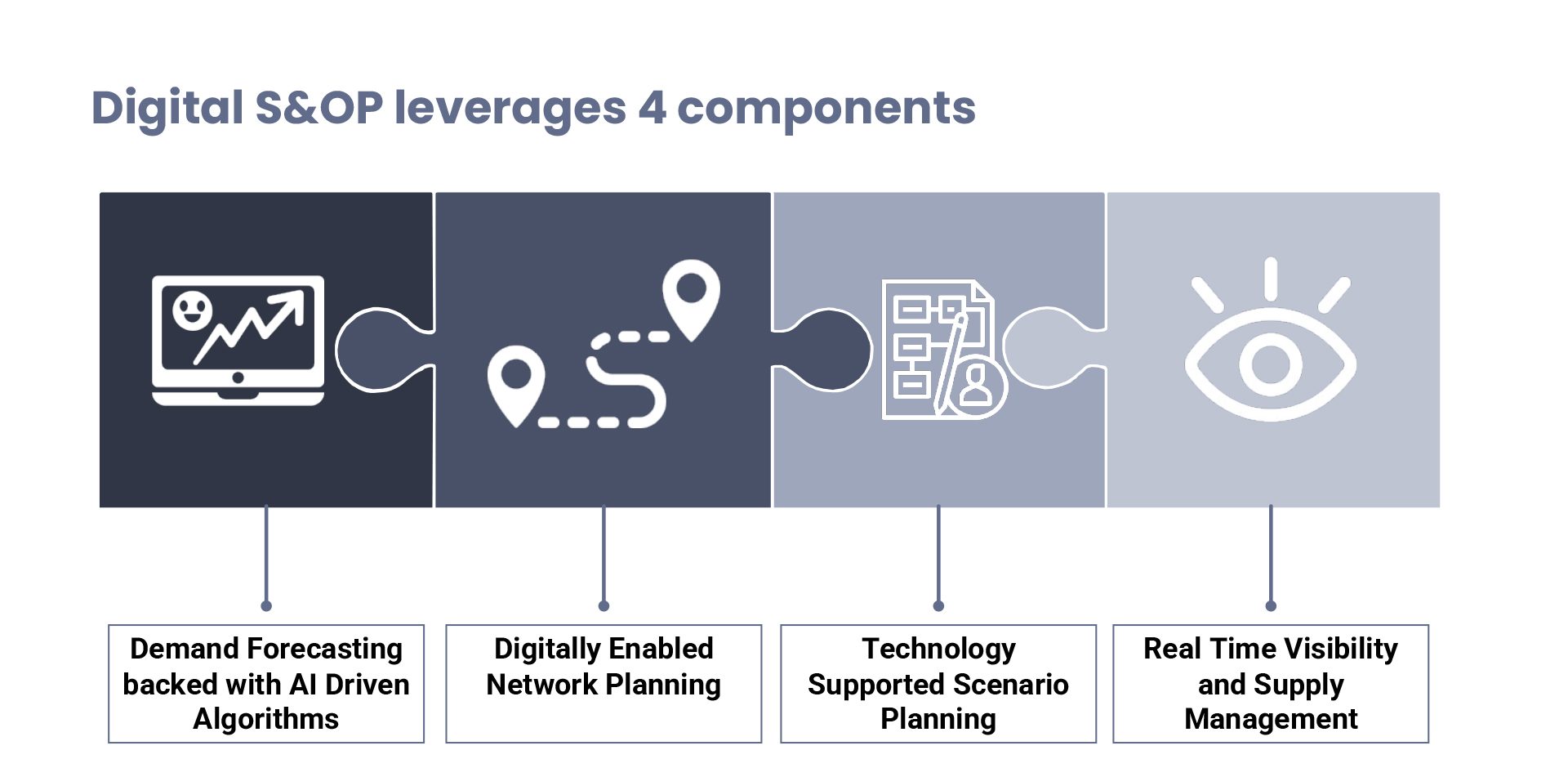

Exhibit 2

Digital S&OP maximizes the value

S&OP creates tangible benefits when it is digitally enabled. Thinking and planning for long-term based on different scenarios is challenging even in very mature and established industries. Every month, without necessary data and technology, going through the same process manually can be a long haul for the teams.

While thinking long term, businesses need to be agile to respond to market needs. In a complex business environment like today, only agile companies can succeed and still be effective in their operations. Agility can be achieved with real time visibility and decision support tools for planning.

At minimum, a digitized S&OP should leverage technology for its 4 key components

Demand Forecasting: Companies need analytics capabilities to analyze historical data, determine and quantify impact of market drivers, and forecast demand for the long term. AI-driven algorithms will learn from historical data and enable data driven forecasts which are further enhanced with insights from sales teams.

Digitally Enabled Network Planning: For companies with multiple production facility and/or warehouses with different capabilities, it is almost impossible to identify the most optimum way of allocating demand with a manual approach. Network planning tools enable businesses to digitally map their network capabilities and immediately see the results of their decisions with underlying assumptions and calculations prior to applying them.

Scenario Planning: Scenarios are the most valuable output of S&OP. Considering market conditions and supply availability, management teams need to see the profitability implications of their decisions. Different commercial decisions lead to different demand scenarios and each demand scenario has an individual supply response. Teams need technology supported scenario planning capabilities to support the decision-making process and optimize the results.

Real-time Visibility and Supply Management: Planning efforts need to be supported with actual results of KPIs. Without knowing how the business is performing, the teams will not be able to make informed decisions. In many companies, data availability, quality and transparency are still major challenges that hinder S&OP value. Tools like end-to-end supply chain planning enables businesses to track actual results and collect relevant, high-quality data for analysis and planning.

Digital S&OP implementation is a journey

Getting to the ideal state requires leadership ownership, time and effort of teams and internalization of new capabilities:

1. Leadership ownership is a must for the success. No S&OP works without top management support and their active involvement in the process. Therefore, leadership team’s support and being role models to the teams are key. Leaders should drive the discussions top-down, ask tough and challenging questions to guide the teams and help the teams to look at the challenges from different perspectives.

2. S&OP requires behavioral change. For S&OP and S&OE teams, it will take time and iterations to start thinking for the long term and discussing proactively for the future risks and opportunities. There should be an effective change management plan in place to track the progress of implementation and understand the challenges of the teams.

3. S&OP requires buy-in from all teams. It is critical to establish a core and permanent cross-functional team (sales, marketing, supply chain, manufacturing, finance, quality, procurement, etc.) who owns the S&OP process and brings perspectives of all functions. Core team is also critical to identify issues in advance and develop solutions.

4. S&OP requires development of new capabilities: High quality analysis, fact-driven and decision-oriented discussions require effective use of data, tools, and analytics. Teams should be provided enough training to develop their both technical and analytical skills.

Overall, S&OP requires effort and focus; however, in a structured and digitized approach the award is great. Companies will have the visibility and consensus about the future of the business across all functions and will be ready for the opportunities and risks in the future while streamlining their operations – they will become a future-ready organization.